Introduction

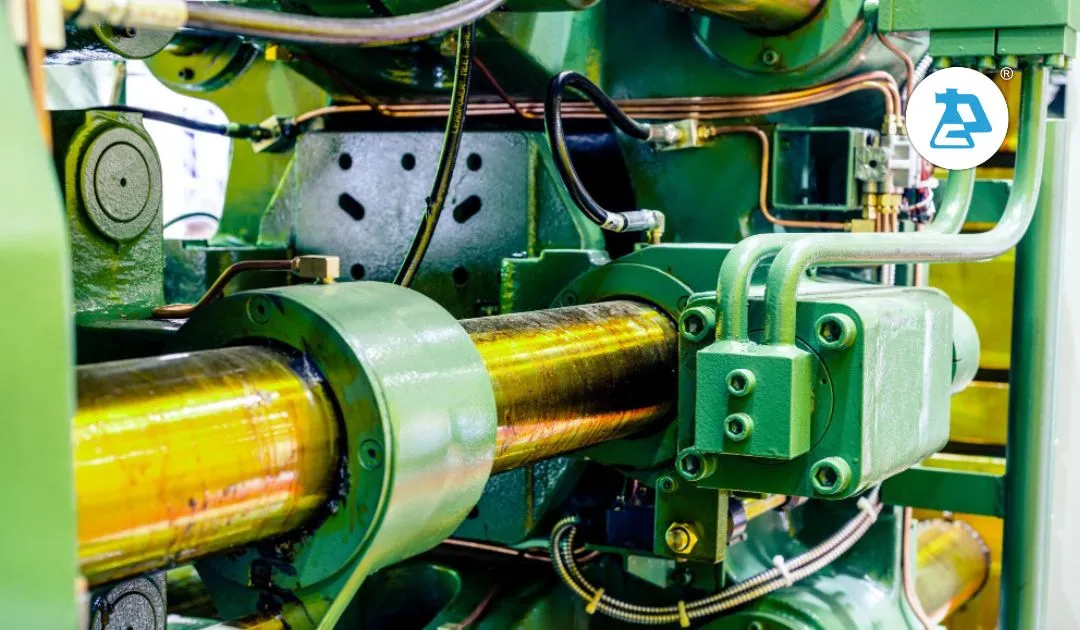

In the intricate world of manufacturing, efficiency and performance are the cornerstones of success. Every component, process, and machine must work seamlessly to achieve desired outcomes. One often underestimated yet paramount element in this equation is the choice of lubricants. High-quality lubricants play a vital role in enhancing efficiency, prolonging machinery life, and ensuring optimal performance across the manufacturing spectrum. In this comprehensive blog, we will explore the significance of quality lubricants in manufacturing and how they contribute to achieving operational excellence.

The Foundation of Efficient Operations

- Reducing Friction and Wear: Friction is the arch-nemesis of efficiency and machinery longevity. Quality lubricants form a protective barrier between moving parts, minimizing friction and wear. Reduced friction translates to less energy consumption, lower maintenance costs, and extended machine life.

- Temperature Regulation: Manufacturing processes generate heat, which can lead to equipment damage and decreased efficiency. High-quality lubricants possess superior heat resistance and thermal conductivity, effectively regulating temperatures and preventing overheating.

- Corrosion Prevention: Manufacturing environments can expose machinery to corrosive agents. Quality lubricants contain additives that protect against rust and corrosion, ensuring the longevity of critical components.

Enhancing Performance

- Improved Power Transmission: In manufacturing, machinery needs to transfer power seamlessly. Quality lubricants ensure smooth power transmission by reducing energy loss through friction and enhancing the efficiency of mechanical systems.

- Consistent Operation: Fluctuations in friction can lead to inconsistent machine operation and suboptimal product quality. Quality lubricants maintain consistent lubrication, contributing to stable and reliable manufacturing processes.

- Precision and Accuracy: Some manufacturing processes require precise movements and measurements. Quality lubricants aid in maintaining precision by reducing vibration and ensuring accurate component alignment.

Operational Efficiency and Cost Savings

- Energy Efficiency: Friction consumes energy and contributes to higher operating costs. Quality lubricants minimize friction, reducing energy consumption and leading to substantial cost savings over time.

- Reduced Downtime: Machinery breakdowns due to wear and poor lubrication can lead to costly downtime. Quality lubricants extend equipment life, reduce wear-related breakdowns, and increase production uptime.

- Maintenance Cost Reduction: When machinery is properly lubricated, it experiences less wear and tear. This translates to fewer repairs and replacement costs, resulting in significant long-term savings.

Product Quality and Compliance

- Cleaner Manufacturing Environment: Quality lubricants have lower volatility and reduced emissions, contributing to a cleaner and safer manufacturing environment. This is particularly important for industries with strict environmental regulations.

- Consistent Product Quality: Lubrication impacts the quality of manufactured products. Proper lubrication ensures that machinery operates consistently, leading to uniform product quality and minimizing defects.

Conclusion

In the dynamic world of manufacturing, achieving efficiency, performance, and excellence is a constant endeavor. Quality lubricants serve as unsung heroes, playing a pivotal role in realizing these goals. By reducing friction, preventing wear, maintaining temperature stability, and ensuring precise operation, quality lubricants elevate manufacturing processes to new heights. They bring about cost savings, reduce downtime, and contribute to a cleaner environment while upholding product quality and compliance. In essence, investing in quality lubricants is not just a choice, but a strategic decision that drives manufacturing success and propels industries toward operational excellence.